Robots are ideal for handling difficult environments, such as the deep sea or post-earthquake zones, or locations where radiation-exposure, explosives, or high voltage are hazards.

Robots have an important role to play in their use in hazardous environments, due to their robustness and ability to endure significantly harsher conditions than humans are capable of. Areas of use range from distaster relief, providing search and rescue in post earthquake or tsunami conditions, or providing rapid mapping capabilities spanning thousands of miles helping locate missing persons, to extreme conditions such as high voltage, radiation, or temperature, where manipulation for performing tasks in such areas is required. Robots can provide an advanced level of interaction with the environment, allowing us to extend our capabilities past our own limitations.

Some of my publications in this area:

Flapping Foils for Marine Propulsion

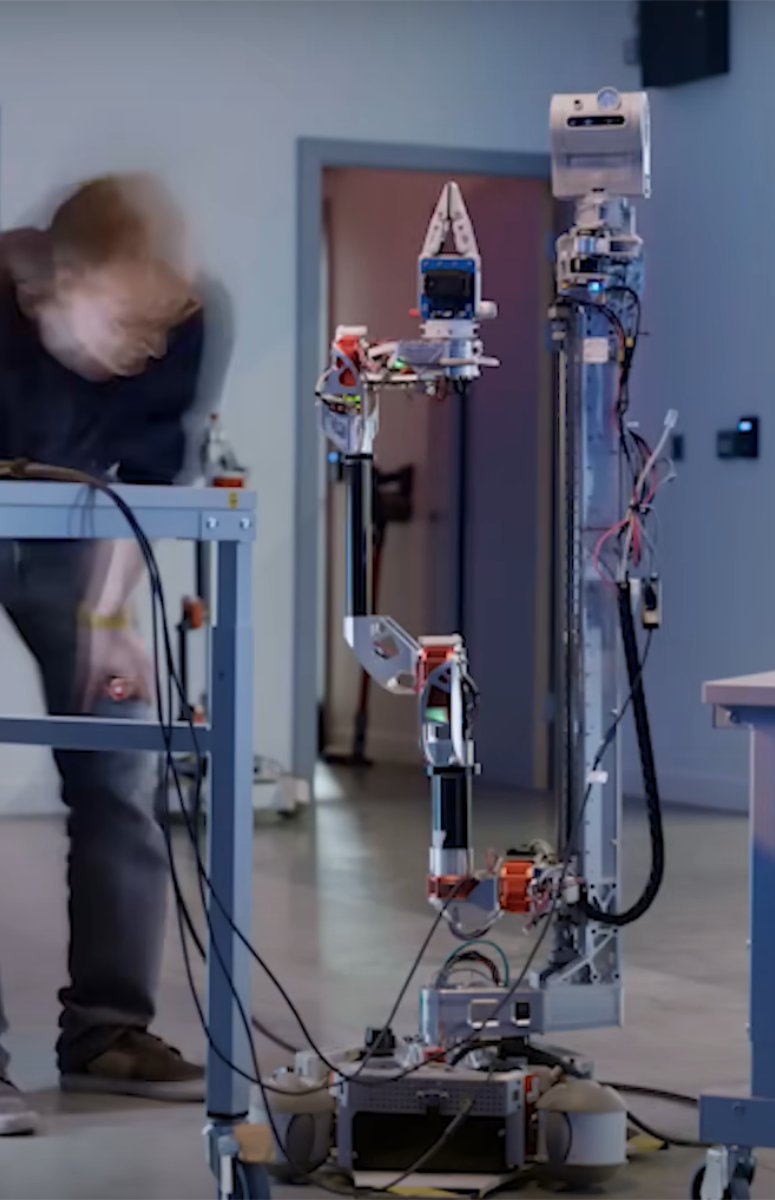

On a balanced delta robot for precise aerial manipulation: Implementation, testing, and lessons for future designs